JewelSuite™ 3D Wellbore Stability/Geomechanics Software

Using the industry-acclaimed JewelSuite™ Modular Geomechanics software, our Wellbore Stability Specialists can model, monitor and forecast wellbore stability during both the planning and drilling phases, and can give RT input into any potential instability issues.

JewelSuite™ — WellCheck

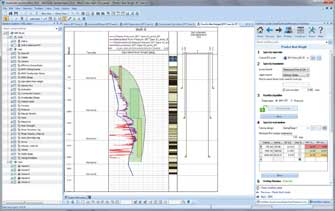

JewelSuite — WellCheck module enables the user to reliably forecast wellbore instability during drilling to mitigate wellbore collapse, tight hole, stuck pipe, excessive hole cleaning, fishing, kicks, lost circulation, formation damage, casing deformation, and sidetracks. You can drill wells with lighter mud weights and fewer casing strings, optimize wellbore trajectory, and lessen nonproductive time (NPT). Optimizing well designs and defining a safe operating window maximizes drilling performance, minimizes drilling risk, and improves safety. The module also helps the user determine what data needs to be refined by improved data collection efforts, and allows for increased confidence in the results of the wellbore stability analysis. With WellCheck software, you can use well logs and drilling data to analyze wellbore stability. To predict mud weight, you can calculate a critical mud weight window and improve casing design by taking into account pore and fracture pressure, rock mechanical properties, and kick tolerance. To check mud weight, you can calculate wellbore failure along the well trajectory from a proposed mud program, considering stress and rock mechanical properties. For quantitative risk analysis, you can calculate the probability of wellbore instability versus mud weight by incorporating the uncertainty of the input parameters.

- Predict mud weight window from lower bound of maximum of pore and collapse pressure, and upper bound of minimum stress for casing design

- Effect of drilling direction on collapse pressure for predict mud weight

JewelSuite™ — PressCheck

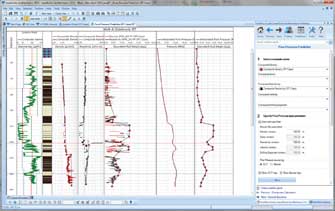

JewelSuite — PressCheck software enables the user to reliably predict abnormal pressure during drilling to mitigate kicks, blowouts, lost circulation, and nonproductive time (NPT). You can optimize your well plans and define a safe drilling window to maximize performance, minimize risk, and improve safety. You can also apply the PressCheck geomechanical model to advanced geomechanical applications such as wellbore stability, full-field geomechanics simulation, bedding-plane failure, and critically stressed fractures/faults. Because of this capability, operators have better insight to optimize the performance of their wells and reservoirs. With PressCheck software, you can use well logs and drilling data to create well-centric geomechanical models consisting of lithology, rock mechanical properties, overburden pressure, pore pressure, minimum and maximum horizontal stress, and fracture pressure. You can display drilling events, manage multiple wells and cases, depth-stretch logs and tops, manipulate logs graphically, analyze local correlations, and create customizable reports.

- Pore pressure prediction from gamma ray zonation model, and trend lines for composite density, and resistivity

- Display wells, sidetracks, logs, and tops in 3-D view

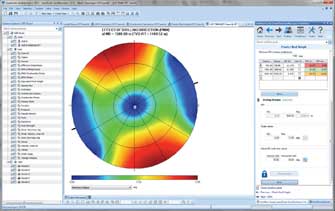

JewelSuite™ — SFIB

JewelSuite — SFIB (Stress and Failure of Inclined Boreholes) software offers full 3-D stress modeling for wellbore breakouts and tensile wall fractures. Forward modeling of inclined drilling-induced tensile wall fractures allows for assessment of the stress state around a wellbore. This also reveals tendency for compressive and tensile wellbore failure. With SFIB software, you can get down to uncommon and uncommonly profitable modeling details. You can include thermal effects and account for rock strength anisotropy in weak bedding planes. SFIB software offers critical stress field knowledge, which is crucial for solving wellbore stability issues, optimizing hydraulic fracture design, and maximizing production. You can collaborate to design optimally stable wellbore trajectories and determine optimal mud weights. This prevents excessive and costly wellbore failures and sidetracks while eliminating intermediate casing strings. More effective early well planning, more comprehensive data usage, and powerful proprietary technology diminishes costly rig time and wasted efforts.