Wellbore Stability / GeoMechanics

HXR offers real-time Wellbore Stability services using modules from the acclaimed JewelSuite™ GeoMechanics software by Baker Hughes. Our office and on-site Wellbore Stability Specialists can model, monitor and forecast wellbore stability of the borehole as it is being drilled, and can give RT input into any potential instability issues.

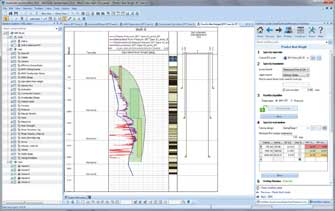

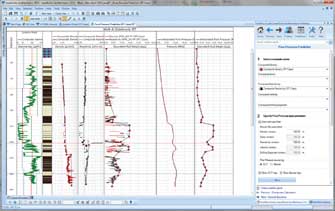

Wellbore Stability design and real-time Wellbore Stability Monitoring services allow operators to reliably identify wellbore instability issues during drilling. Using LWD logs and drilling data, our WBS Specialists create highly accurate geomechanical models consisting of lithology, rock mechanical properties, overburden pressure, pore pressure, minimum and maximum horizontal stress, and fracture pressure. These models are used to help mitigate wellbore collapse, tight hole, stuck pipe, excessive hole cleaning, fishing, kicks, lost circulation, formation damage, casing deformation, and sidetracks. Wells can be drilled with lighter mud weights, fewer casing strings, optimum wellbore trajectory, and less nonproductive time (NPT). Optimizing well designs and defining a safe operating window maximizes drilling performance, minimizes drilling risk, and improves safety. The probability of wellbore instability for a given MW can be calculated, and even more advanced models, such as bedding-plane failure and critically stressed faults, can be generated. Using WITSML, real-time data can easily be collected, edited, and input to the models.

Lost hole sections and repeated stuck pipe/lost BHA events on a single well can be the end of an entire drilling project.

Applications

- Offshore drilling

- Exploration drilling

- High-angle and extended reach drilling

- Underbalanced drilling

- Complex geology

- Depleted reservoirs

- Environmentally sensitive areas

- Wells in areas of intense stress regimes

Benefits

- Accurate calculation of rock properties, overburden, formation pore and

fracture pressure, and horizontal stress from well logs and drilling data - Minimizes risk and improves safety during drilling

- Identification of wellbore stability issues in both the predrill design and real time during the drilling phase

- Optimizes wellpaths

- Identifies safe mud weights

- Decreased NPT

- Decreased lost hole sections / redrills

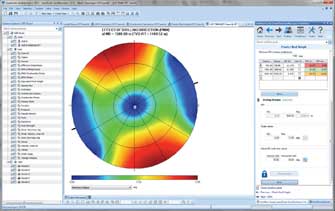

- Effect of drilling direction on collapse pressure for predict mud weight

- Predict mud weight window from lower bound of maximum of pore and collapse pressure, and upper bound of minimum stress for casing design

- Pore pressure prediction from gamma ray zonation model, and trend lines for composite density and resistivity